A holistic solution to the emission issue

Reducing emissions is a patchwork process that has to occur in many places at once, so you need to know where which emissions are generated if you want to save CO2. A helpful tool in this regard is the internationally recognized Greenhouse Gas Protocol10, a universally applicable standard developed under the leadership of the World Resources Institute and the World Business Council for Sustainable Development, which categorizes greenhouse gas emissions as Scope 1, Scope 2, or Scope 3.

Scope 1 comprises all those emissions for which a company itself is responsible and over which it therefore has direct control. One example is energy sources that are consumed on site for the operation of furnaces or plants, including for the company’s own vehicle fleet.

Scope 2 includes all those emissions that result from purchased energy. One example is electricity that is purchased from power plants for the operation of HVAC systems. Another example is district heating that is purchased to heat office buildings.

Scope 3 is the trickiest area and is often excluded from climate-neutral labels. It includes those indirect emissions that result from the manufacture of upstream products as well as those from downstream use of the company’s own products. Such emissions are difficult to calculate and the options to regulate them are limited. One way of controlling them is to use supplier requirements.

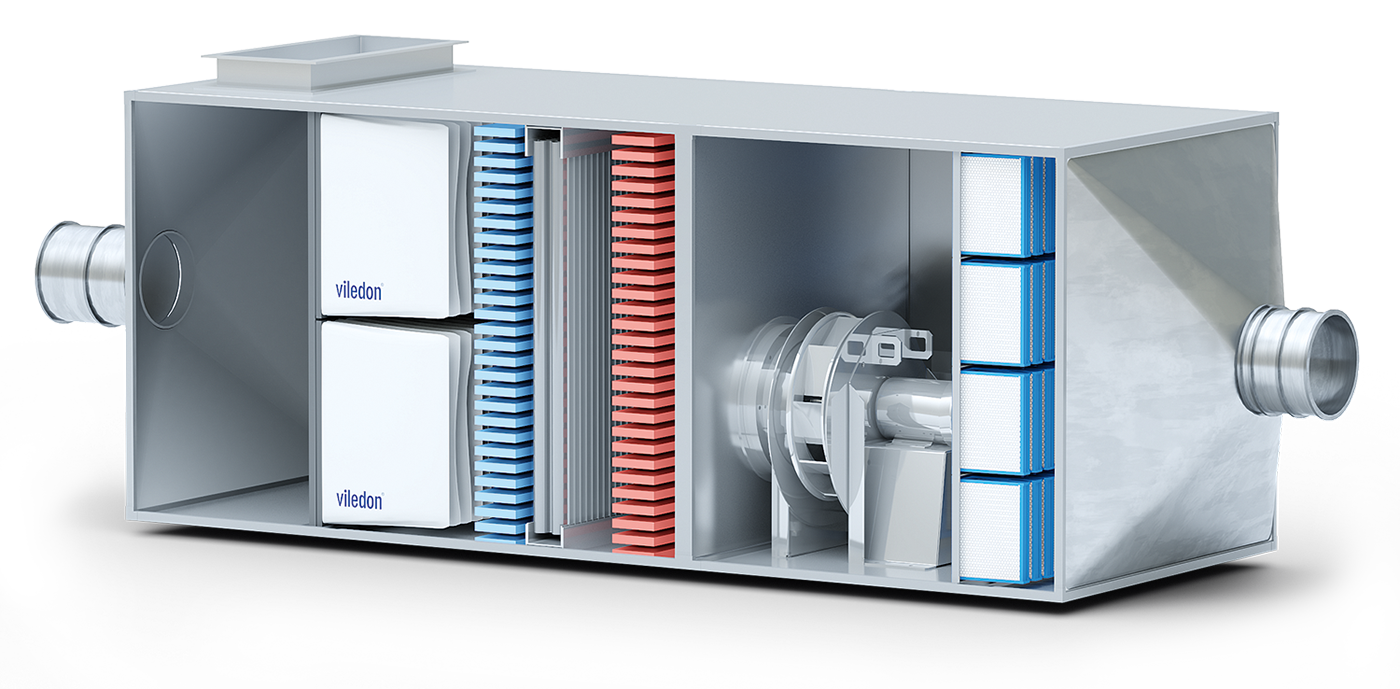

Many emission sources (e.g. HVAC systems, which supply rooms and processes with constantly clean air) cannot simply be switched off. Saving energy through sophisticated, high-efficiency filtration systems are particularly important in this case.