They account for around half of the energy costs incurred by commercial buildings. Although they do not consume electricity directly, filter elements alone account for 16 percent of consumption. The greater a filter’s air resistance, the harder the fan must work to circulate a defined volume of air. This is known as pressure drop and increases the longer the system is in operation. This is because the flow resistance rises as fouling of the filter builds up.

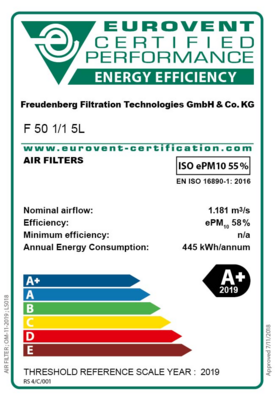

This depends primarily on its filtration performance and design. High-quality filter elements often have a lower pressure drop than low-cost filters. Eurovent Certita Certification provides certification in the fields of heating, ventilation, air conditioning, and refrigeration. It has developed the RS 4/C/001-2019 evaluation standard, which defines energy efficiency classes from A+ to E for air filters. This allows the comparison of filters in terms of energy consumption. The energy consumption of air filters is determined and evaluated to provide a basis for specifying energy efficiency. These basic principles are described in Guideline 4/21, issued by the Eurovent Association, which is the European umbrella organization for manufacturers in the ventilation, refrigeration, and air conditioning sectors.

According to Eurovent, energy costs account for around 80 percent of the total cost of a filter. The actual acquisition cost constitutes just ten percent of the total cost. Maintenance and disposal are responsible for the remaining ten percent. Energy-efficient filters therefore pay for themselves even if they are significantly more expensive to purchase. Cheap models also often have a shorter service life.

Energy-efficient filters’ combination of longer service life and lower pressure drop makes them the best choice if you are looking to optimize cost efficiency. Freudenberg Filtration Technologies offers a broad portfolio of such filter elements for HVAC systems. These elements consume very little energy and boast long service lives, so taking the wise decision to install them reduces both energy costs and emissions.

Source:

VDMA Luftfilterinformation – Energieeffiziente Luftfiltration – Kosten sparen durch effiziente Luftfilter