Better commuting through filtration

This demands a wide range of filter properties. Filters must meet legally stipulated fire protection regulations, have good filtration properties, and a long service life. The longer a filter can remain effective in operation, the less maintenance is required. Coarse filters have therefore been the primary choice for filtering large particles and pollen from the air until now. The low pressure drop of such filters ensures low energy consumption for the ventilation system. However, the filtration performance of coarse filters is limited. They do not provide the required level of retention for hazardous fine dusts, and this requirement is even more critical during the winter months.

Operators want a viable solution that combines filtration performance and cost efficiency.

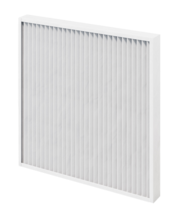

Freudenberg Filtration Technologies has developed filter panels made of synthetic material that filter around 50% of PM10 fine dust (measured in accordance with ISO 16890) from the intake air with a low pressure drop. The filter panels are easy to replace — the process takes no time at all. Passengers benefit from a significantly improved indoor climate in trains, while the operator benefits from reduced maintenance costs as a result of less frequent filter changes.