Caution: highly flammable

Organic materials such as grain and sugar, but also many chemicals and light metals, are combustible. Their dust can be explosive given the right mixture of air. The lower the amount of energy required to ignite a dust, the greater the danger. A small spark is often enough. The EU “ATEX” directives stipulate the legal conditions for explosion protection to increase safety in plants. These comprise the ATEX Workers’ Protection Directive (1999/92/EC) and the ATEX Equipment and Protective Systems Directive (2014/34/EU), and regulate which areas in industrial plants should be classified as potentially explosive, and which equipment, components, and protective systems may be used in such areas. The areas are divided into different zones based on risk, explosive gases and dusts are additionally classified in explosion groups. Corresponding measures are stipulated for each zone and group with the goal of attaining maximum safety.

Conductive is the magic word

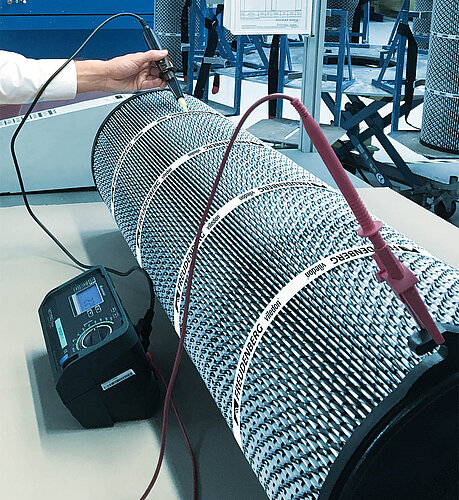

Air filtration and dust removal systems can be found wherever there is dust. Only filter elements that meet certain electrostatic properties may be used if such areas fall under the “ATEX” directives. For example, if parts were to become electrostatically charged, the friction between the dust and the filter would create a risk of sparking — and thus of igniting the explosive atmosphere. Maximum safety can be achieved by using conductive filter elements that are integrated into the grounding system. That is why the ATEX-compliant filter elements and filter cartridges from Freudenberg Filtration Technologies are electrically conductive.